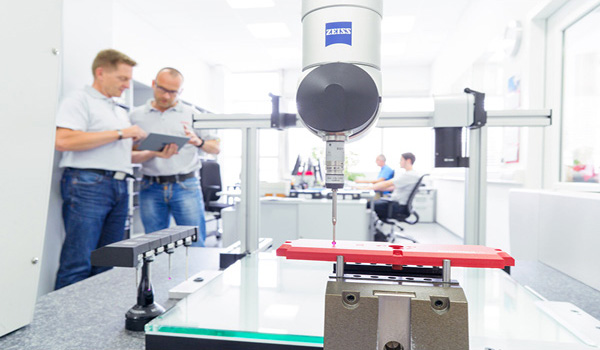

Quality assurance at EUCHNER begins even before production. All potential materials and components for our products are first subjected to extensive load tests in our laboratory. Only once they have passed all of the tests are they approved for subsequent use.

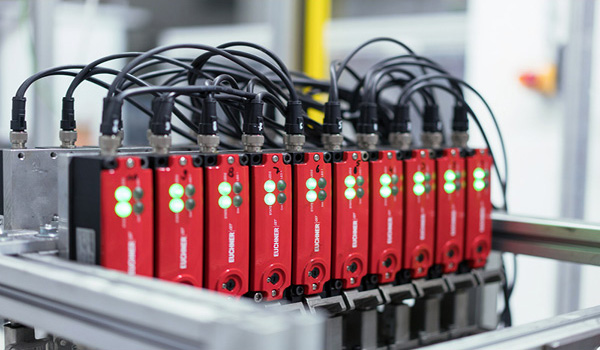

Finished products also undergo a whole raft of inspections before leaving our production operation. We use cutting-edge technology and our own test processes to put them through extremely stringent quality controls – and quite rightly.

Our ISO 9001 certification and internal quality management system support the process. Annual TÜV audits are yet another way for us to keep improving and to maintain our quality standards for the long term.

We make sure our customers get what they expect from EUCHNER: top quality.

Insights into our quality management