Safe automation despite increasing requirements

At SPS in Nuremberg (November 25 to 27), EUCHNER will be exhibiting innovative safety products for automated production at Booth 280 in Hall 7. The company’s solutions meet the latest communication requirements in networked processes. They can be seamlessly integrated to provide the best possible protection for people, machines, and plants.

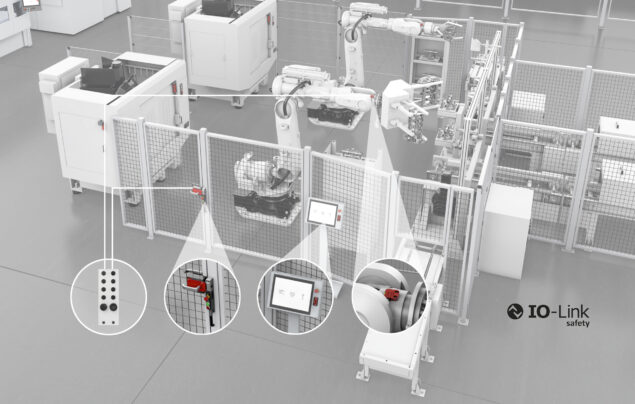

EUCHNER has combined its proven, robust safety components with the benefits of safe communication via IO-Link Safety.

Increasing demands for more flexibility, productivity, and availability are accompanied by ever more complex safety engineering, putting manufacturers of plants and machines under huge pressure. EUCHNER ensures safe end-to-end communication from the control system through to the sensors with its robust components and IO-Link Safety. This standardized, non-proprietary interface allows switches and guard locking and door systems to be connected efficiently, resulting in a significant reduction in planning and installation work. Comprehensive diagnostic functions also simplify troubleshooting, reduce maintenance costs, and increase plant availability.

Networking without limits

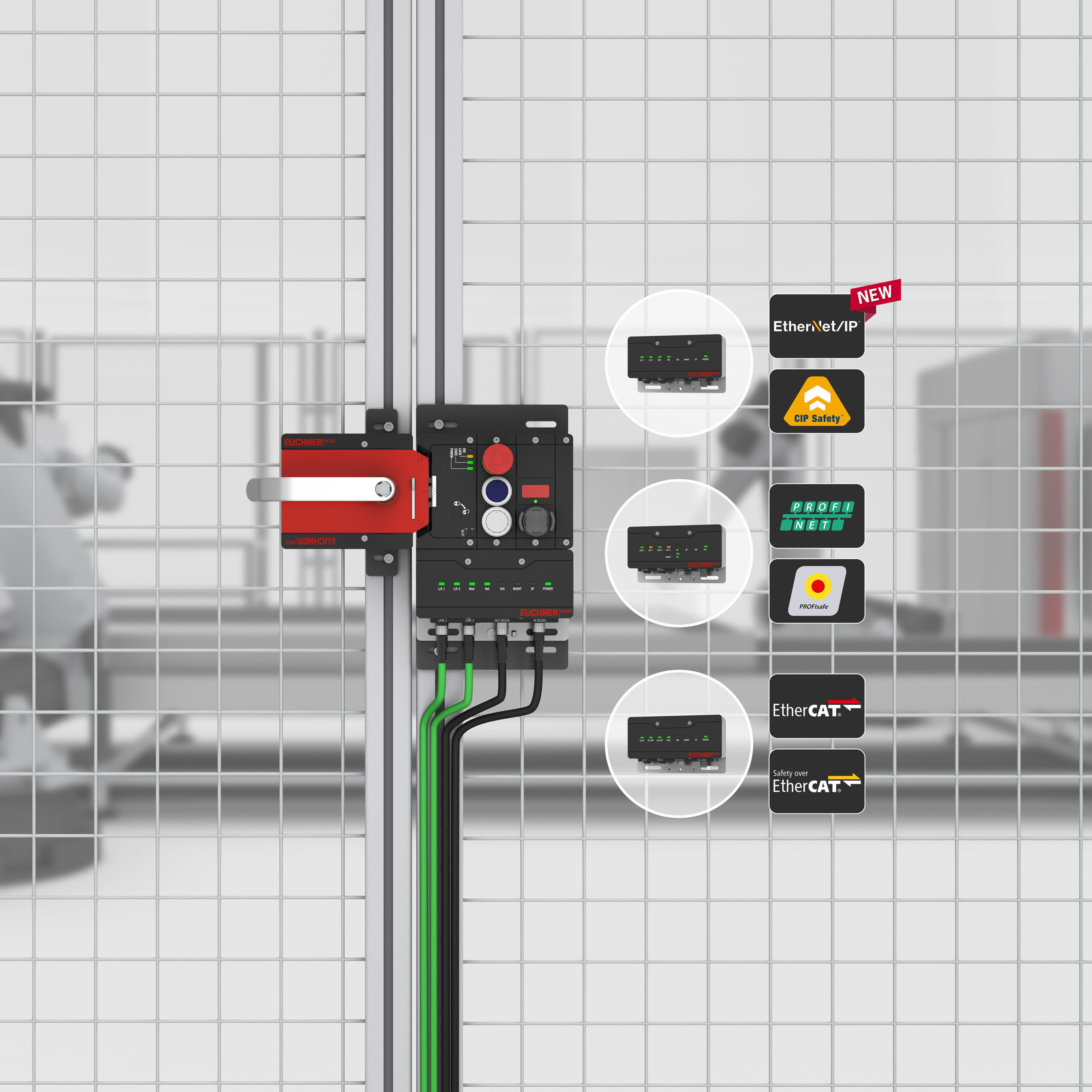

At its booth, EUCHNER will also be exhibiting its safety door system MGB2 Modular, which has the flexibility to adapt to changing requirements. It can be seamlessly integrated into PROFINET, EtherCAT (P), and EtherNet/IP networks and is designed to be compatible with all current control system architectures. An integrated Ethernet switch reduces the amount of wiring needed and simplifies the network topology. In addition to access control, the MGB2 Modular also allows for machine operation and signaling. It is robust (temperatures as low as -30 °C, IP65) and complies with safety level PL e/SIL3.

With the EKS2, the latest generation of the Electronic-Key-System from EUCHNER, users can easily manage and customize access to machines and their functions and ensure that they are secure against tampering.

The Electronic-Key-System EKS2 from EUCHNER is a central access management solution that is secure against tampering and is designed for networked production environments with variable roles and shift schedules. If access is not actively managed, the system prevents incorrect operation, downtimes, and safety gaps. In combination with the Electronic-Key-Manager EKM2 and the integrated database, the Electronic-Keys can be managed flexibly from a PC. Predefined templates, data encryption, hygienic IP69 design, and the direct PROFINET connection simplify the integration of the system into existing automation solutions.

Flexible and versatile

Visitors to the EUCHNER booth will also have the opportunity of finding out more about the CTS compact safety switch. This has an impressive locking force of up to 5,000 newtons and can be installed in a variety of ways in hinged and sliding doors. Its actuator, which is mounted on a floating bearing, can withstand vibration and offset mounting. The FlexFunction allows for a variety of applications with only one device. In the past, these applications would have required several switch variants. The safety switch is accompanied by a comprehensive range of accessories, including an extendable escape release, a lockout mechanism, and mounting plates, which enable the flexible installation of the CTS and the actuator. An installation kit with a handle simplifies the integration of the safety switch into access doors. There is also a variant with a mounting magnet that keeps accesses closed even in the event of heavy vibration and prevents unwanted noise. With different connections available, the safety switch can be directly connected to decentralized fieldbus modules and other control systems.

Become a safety expert

The EUCHNER Safety Services add the finishing touch to the company’s presence at the trade fair. Visitors can test their knowledge of safety engineering by taking a safety quiz at the EUCHNER booth and by identifying safety defects on the 3D model of a machine.

The company also demonstrates how, with its Safety Services, it supports its customers throughout the world on all issues relating to machinery safety and the new EU Machinery Regulation. There is also the opportunity of training to become a TÜV-certified expert in production and machinery safety. For more information and registration options, visit: www.euchner.de/en-us/about-euchner/dates