Automation – Sure Thing!

Plant construction and mechanical engineering companies are currently under enormous pressure: increasing demands on flexibility, productivity and availability are coupled with ever more complex safety requirements. That’s why modern automation needs safe, scalable solutions with communications capability. This is where EUCHNER comes in. Our innovative safety products can be seamlessly integrated for optimum protection of people, machines and processes.

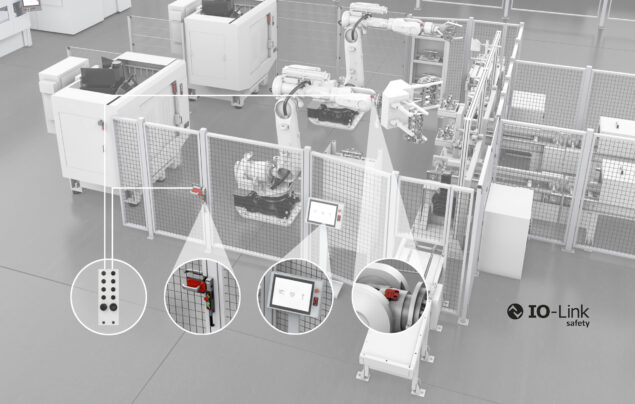

By combining robust safety components and IO-Link Safety, EUCHNER is opening up new possibilities for continuous, safe communication in automation, from control systems right through to sensors. Switches, guard-locking devices and door systems can be connected efficiently using a uniform, standardized interface, reducing planning and installation work significantly. The safe transmission of actuator and Electronic-Key data opens the door to completely new applications. What’s more, comprehensive diagnostic functions make troubleshooting easier and reduce maintenance work, which in turn increases machine availability.

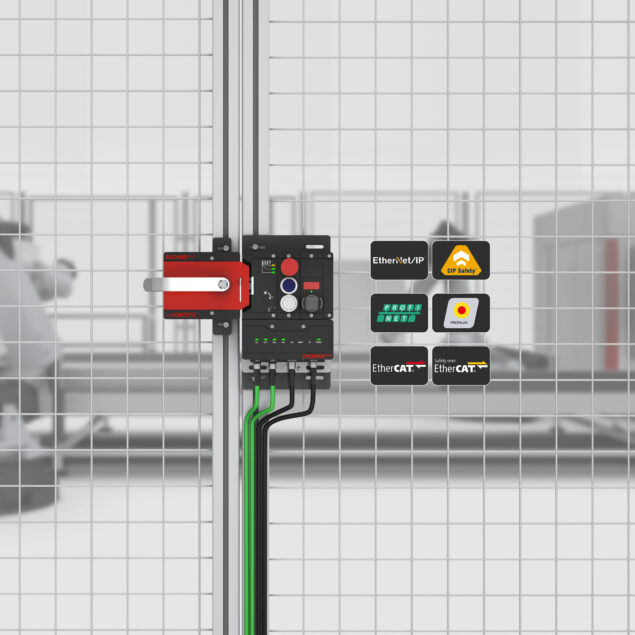

Networking without limits

Machine and installation designs are evolving – and the MGB2 Modular is keeping pace. The fully modular safety door system can be flexibly adapted to changing requirements. Thanks to seamless integration into PROFINET, EtherCAT (P) and EtherNet/IP, the system can be designed for all standard control system architectures without the need for additional gateways. An integrated Ethernet switch reduces the amount of wiring work and simplifies the network topology. The MGB2 Modular offers access control, operation and signaling all in one device, is extremely robust (as low as -30 °C, IP65) and achieves the highest possible safety level (PL e / SIL3). It is ideal for modular production lines, line conversions and retrofit projects – to name just a few.

Digital access control for smart factories

Users who do not actively control access to machines risk improper operation, downtimes and safety gaps. The new Electronic-Key-System EKS2 offers central access management that is secure against tampering for networked production environments with variable roles and shift schedules. In combination with the new Electronic-Key-Manager EKM2 and the integrated database, the keys can be managed flexibly on a PC. Predefined templates, data encryption, hygienic IP69 design and direct PROFINET connection allow highly efficient integration of the electronic key system into existing automation solutions.

Safety expertise

Machine manufacturers and operators must comply with European directives, as well as national and international standards. EUCHNER’s Safety Services are on hand with professional solutions for customers worldwide, covering all aspects of machinery safety and the new Machinery Regulation. Our EUCHNER Academy also offers training for those wishing to qualify as a TÜV-Certified Expert in Operational Safety and Machinery Safety. There are another four training sessions in the second half of this year: https://www.euchner.de/en-us/about-euchner/dates/