Rope pull switch RPS-C

Description

RPS-C rope pull switches are EMERGENCY STOP devices for safeguarding large and extensive machine or system areas that cannot be safeguarded by an enclosure or cover. In the event of danger, plant or machine areas can be shut down immediately from any point in the working area.- Emergency stop device with detent mechanism in accordance with 13850

- Compact and space-saving

- Switching elements with up to 4 switching contacts

- Quick and easy mounting; assembly using the quick-release head

- EMERGENCY STOP button available directly on the switch

Task of rope pull switches

In contrast to switches with an emergency stop button, the triggering range is many times greater, as actuation is possible over the entire length of the rope and is not limited to the small area within reach of the switch. Rope pull switches are used wherever extensive danger areas need to be protected and an enclosure or cover is not possible or would be disproportionately expensive. The advantage is that plant or machine areas can be shut down immediately from any point in the work area in the event of danger, where otherwise individual EMERGENCY STOP controlgears would have to be installed at short intervals.

The advantage is that plant or machine areas can be shut down immediately from any point in the work area in the event of danger, where otherwise individual EMERGENCY STOP controlgears would have to be installed at short intervals.

Function and technology of rope pull switches

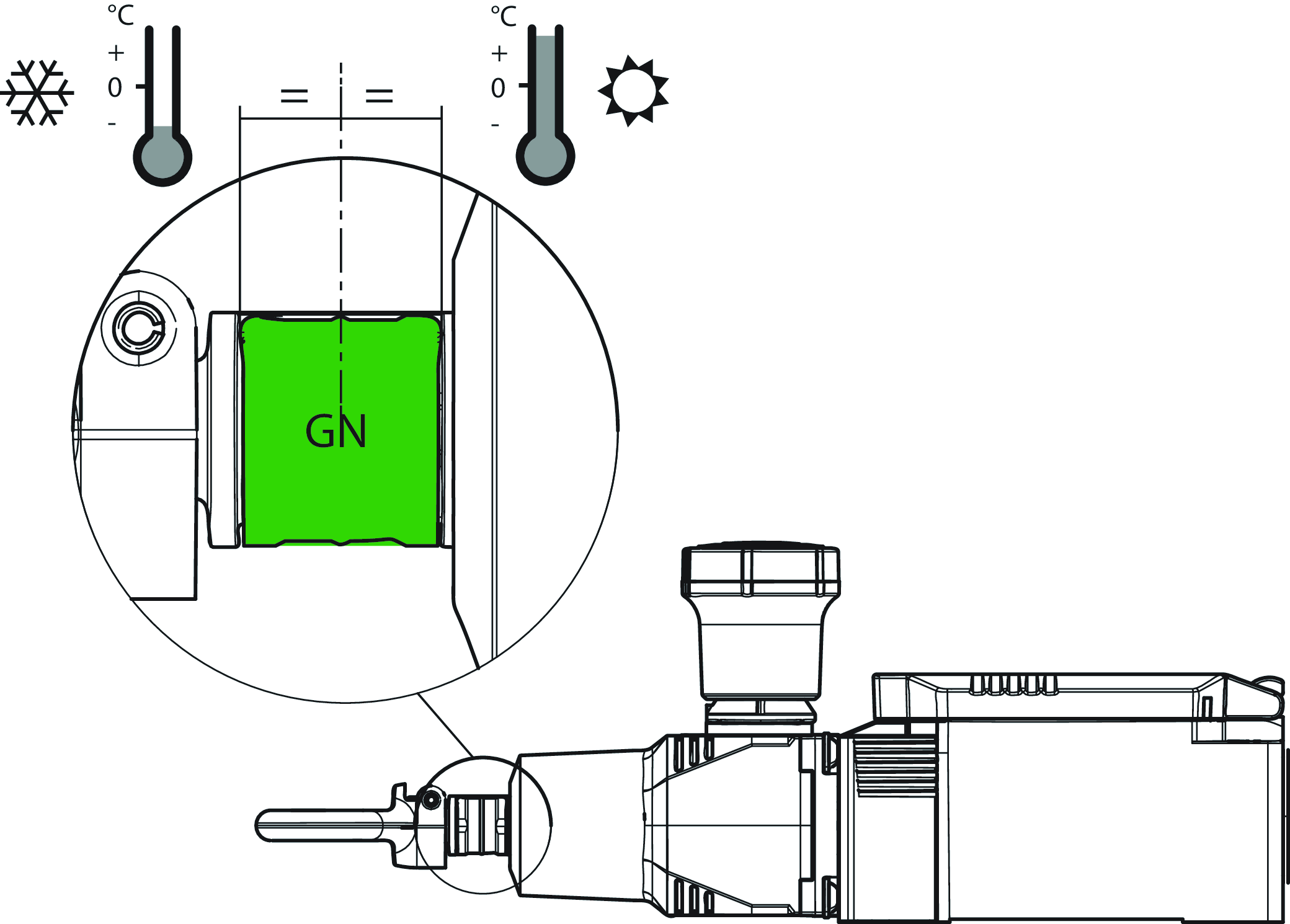

EN 60947-5-5 - 6 (Requirements for EMERGENCY STOP pushbuttons and rope pull switches) places certain requirements on a rope pull switch, which ultimately determine its function. For example, the reset of the latching device (emergency stop button) must be carried out by turning a key, by turning the pushbutton in the specified direction or by a pulling movement. Rope pull switches are normally activated by pulling on a plastic-coated steel cable (known as a safety rope or pull cord). In addition, EUCHNER's rope pull switches have an EMERGENCY STOP controlgear on the housing, which has the same effect. When activated, the safety contacts are actuated and a stop signal is generated, which switches the machine off. The vertical tensile force acting on the wire or cable must be less than 200 N to generate the EMERGENCY STOP signal (opening of the contacts). The vertical deflection of the wire or rope required to generate the EMERGENCY STOP signal must be less than 400 mm. Similarly, a break or unhooking of the wire or rope must generate an EMERGENCY STOP signal. This ensures that a defect in the safety system is detected immediately and the safety function is not lost at any time. To achieve this, the rope pull switches have a center position and two switch-off positions. During machine mode, the switch is in the center position. If the safety rope is pulled or breaks, the switch moves from the center position to one of the switch-off positions and the machine is stopped. The rope tension is indicated by a green field, which is visible when the rope is tensioned.

To achieve this, the rope pull switches have a center position and two switch-off positions. During machine mode, the switch is in the center position. If the safety rope is pulled or breaks, the switch moves from the center position to one of the switch-off positions and the machine is stopped. The rope tension is indicated by a green field, which is visible when the rope is tensioned.

Attachment and rope attachment

Attachment

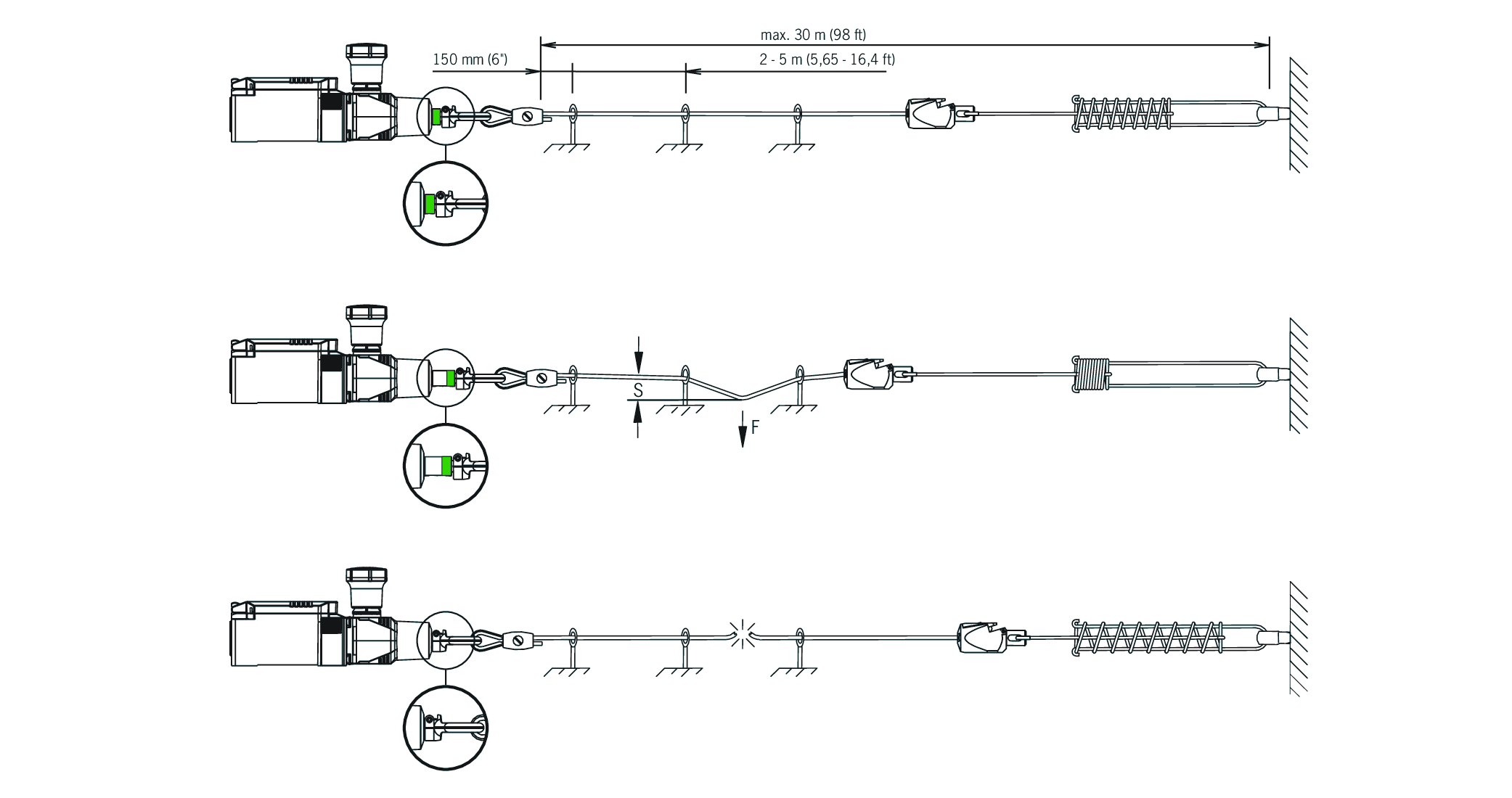

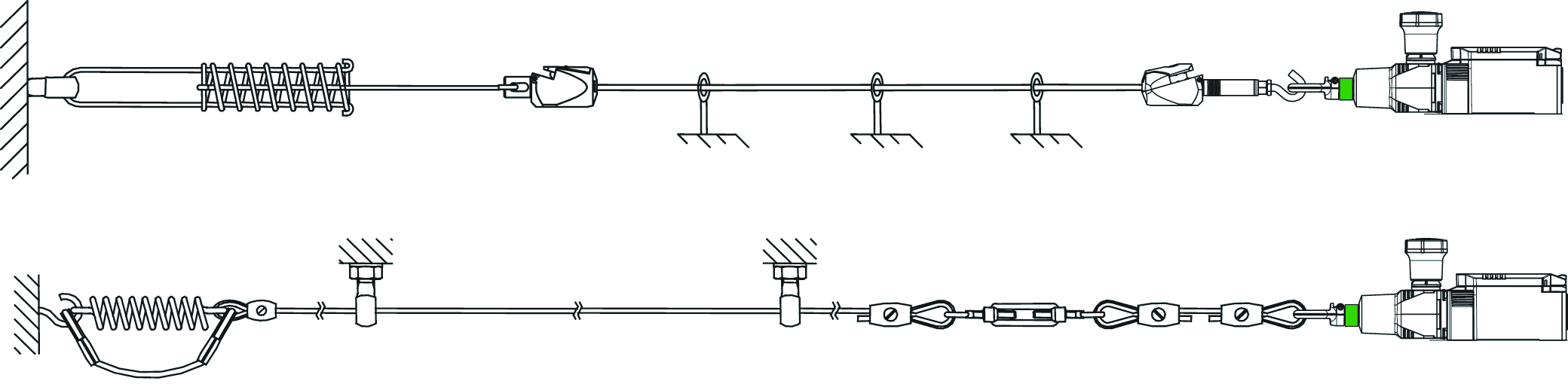

According to EN ISO 13850, EMERGENCY STOP controlgears must be positioned in such a way that they can be easily reached and safely actuated by persons at risk. If, as with rope pull switches, wires/wire ropes or lines are used, it can be useful to attach marker flags to improve their visibility. For a proper and safety-compliant version of the pull-wire system, a tensioner spring must be provided on the counter bearing. This enables direction-independent activation at any point along the rope section.Rope attachment and quick-release head

Version RPS-CThe rope can be connected to the RPS-C using the quick-release head (optional accessories).

- Insert the rope into the quick-release head

- Secure the quick-release head and connect it to the RPS-C

- Attach the pull wire to the counter bearing with tensioner spring or counter spring and guide through the support points.

- Use the Turnbuckle to clamp the cable until the indicator is between the markings. Unlock the device by pulling the reset button; the green label should be completely visible.

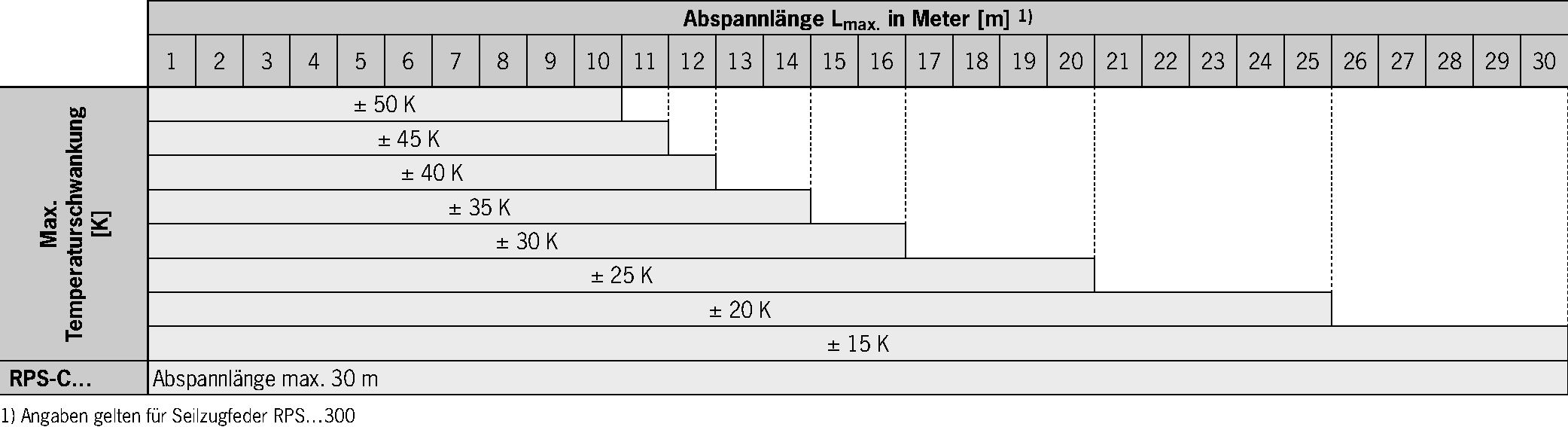

Rope length and temperature dependence

When planning safety devices with rope pull switches, the temperature dependency of the system and the safety rope must be taken into account to prevent the switch from being activated due to temperature. For this purpose, the possible rope length must be determined and the trigger point adjusted regularly. Mounting; assembly should be carried out at a temperature of 20°C.

Termékek (2)

Nem található eredmény

174755

RPS-C-2131SR95M-174755

Rope pull switches with guard locking for emergency stop devices

RPS-C-2131SR95M-174755

Rope pull switches with guard locking for emergency stop devices

- Plastic housing

- Emergency stop device with detent mechanism as per EN ISO 13850 and EN 60947-5-5

- Rope clamp for pull wire

- Cable entry M20 x 1.5

- Switching elements with 4 switching contacts

174757

RPS-C-538SR95M-174757

Rope pull switches with guard locking for emergency stop devices

RPS-C-538SR95M-174757

Rope pull switches with guard locking for emergency stop devices

- Plastic housing

- Emergency stop device with detent mechanism as per EN ISO 13850 and EN 60947-5-5

- Rope clamp for pull wire

- Cable entry M20 x 1.5

- Switching elements with 2 switching contacts